- NISSAN

- MAZDA

- SUZUKI

The main point in a development and a design

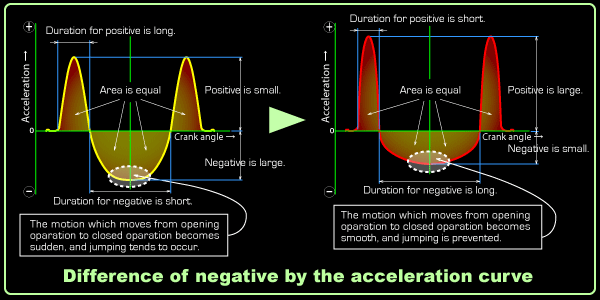

You have to raise "filling efficiency", in order to obtain a high output. Being required of a cam is lengthening time which the valve's is opening. It is necessary to increase the amount of cam lifts in order to lengthen time which the valve is opening. The negative acceleration will become large if the amount of lifts is increased simply. The "jumping phenomenon" in which a valve separates from a cam, and the "bounce phenomenon" which is bounded when a valve contacts a valve sheet ring occur because when negative acceleration becomes large, the acceleration of a valve will exceed the acceleration of a cam. These phenomena not only spoil the performance of engine original but cause breakage of engine. The high camshaft must realize the conflicting element with which "extension of time which is opening the valve", and "reduction of negative acceleration".

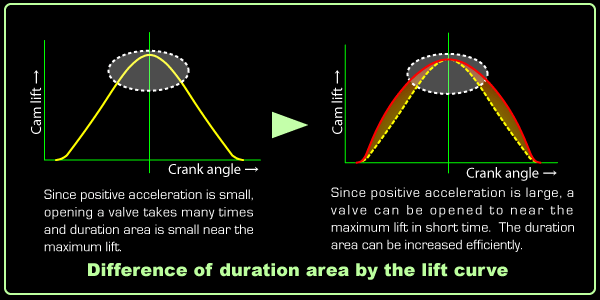

JUN high camshaft took positive acceleration large , and the action time of negative acceleration is keep a long time by shortening positive action time. By doing so, when a valve moves from opening operation to closing operation, a valve can move as smooth operation and can prevent jumping. Since positive acceleration becomes large at the side of close, the valve just before closing is added the strong brakes by the cam. The bounce phenomenon is prevented. The time near the maximum lift can be kept for a long time by opening a valve in a short time.

Therefore, the good valve motion of efficiency is possible. The simulation and an experiment of the valve motion system are conducted based on such design theories, and a profile is determined. Here is the true performance for which a high lift camshaft is asked.

Developing in substantial environment

Even if it says a camshaft in a word, the profile form is various by the type of a car. Profile form is decided in consideration of the difference of valve motion method etc. (direct type, a locker arm type, strength of moving part, valve size, port and combustion room form). If depending on types of a car, a profile may be restricted by the wall in a head, lifter hole size, locker arm form, etc. At JUN, when developing a high camshaft, the detailed data for each type of a car is taken, development is furthered simultaneously with a valve spring and retainer, and the optimal profile is determined.

A high effective grinder and a quality contrl

In order to manufacture a highly precise camshaft, it can be said that the cam grinder with a high performance is indispensable. In our company, the CNC master less grinder with high processing accuracy was introduced from the early stage, and the camshaft has been manufactured. Since the camshaft grinder of our company can input the program data of a cam profile very finely, it can grind in the cam profile based on a design. The quality control is performed on the high standard like other products. The user is provided with the high product of quality.